Foil Type Strain Gauge

PMFLS Series Asphalt Mold Strain Gauges

These mold strain gauges are embedded in asphalt for use in such applications as loading tests with rolling compaction. Material used in the backing is super engineering plastic featuring water and heat resistance. The gauges can withstand a high temperature of up to 200℃ during placing of asphalt.

Gauges are temperature-compensated for asphalt.

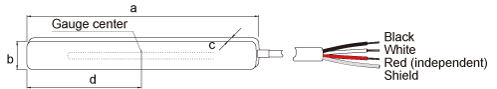

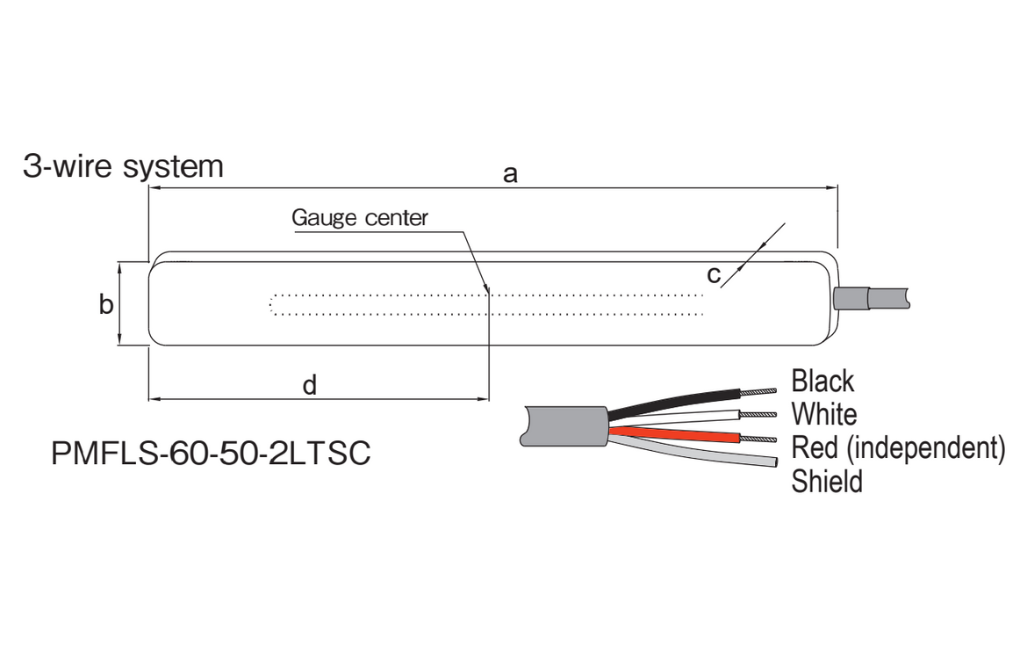

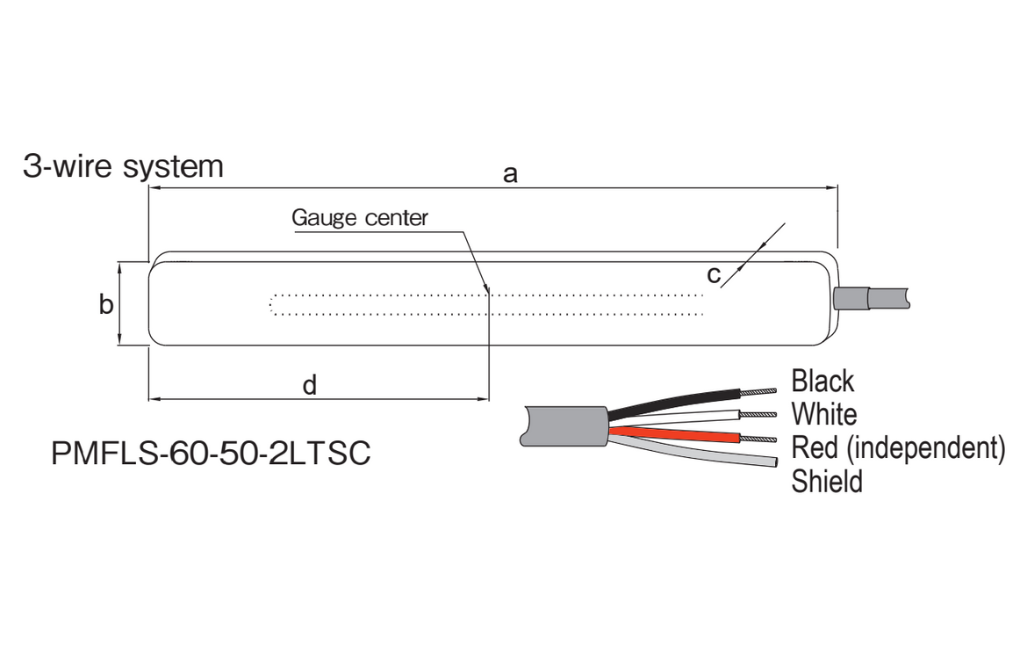

| Type | Gauge length (mm) |

Gauge width (mm) |

Backing length a (mm) |

Backing width b (mm) |

Backing thickness c (mm) |

Gauge center d (mm) |

Resistance value (Ω) |

|---|---|---|---|---|---|---|---|

| PMFLS-60-50-2LTSC | 60 | 1 | 120 | 13 | Approx. 7 | 60 | 120 |

KM Strain Transducer

The KM series strain transducers are designed to measure strain in materials such as concrete, synthetic resin which undergo a transition from a compliant state to a hardened state. Their extremely low modulus (KM-M:25N/mm2) ,(others:40N/mm2) and waterproof construction are ideally suited for internal strain measurement during the very early stages of curing. They are totally impervious to moisture absorption, producing excellent stability for long-term strain measurement. Relative temperature measurement is also possible with the KM-B. The built-in thermocouple sensor of the KM-BT enable actual temperature measurement in addition to strain measurement.

| TYPE | KM-30 | KM-50F | KM-100B | KM-100HB | KM-100BT |

|---|---|---|---|---|---|

| Capacity | ±5000×10-6 strain | ||||

| Gauge Length | 31mm | 50mm | 100mm | ||

| Rated output (Approximately) | 2.5mV/V 5000×10-6 strain | 4mV/V 8000×10-6 strain | 2.5mV/V 5000×10-6 strain | ||

| Non-linearity | 1%RO | ||||

| Apparent elastic modulus | 40N/mm2 | ||||

| Strain measurement | 120Ω Half bridge | 350Ω Full bridge | |||

| Temperature measurement | – | *¹Strain gauge (350Ω Quarter bridge 3-wire method :50x 10‒6 strain/°C) | *² Thermocouple T | ||

| Allowable temperature range | -20 ~ +60°C | -20 ~ +80°C | -20 ~+180°C | -20 ~ +80°C | |

| Input/Output resistance | 120Ω (Half bridge) | 350Ω Full bridge | |||

| Weight | 12g | 45g | 75g | 80g | 75g |

Input/Output cable:

KM-30 φ2.4mm 0.04mm2 3-core shielded vinyl cable 2m

KM-50F φ6mm 0.35mm2 4-core shielded chloroprene cable 2m

KM-100B φ9mm 0.3mm2 5-core shielded fluoroplastic cable 2m

KM-100BT φ9mm 0.3mm2 4-core shielded T-thermocouple compound cable 2m